For detailed information, other images and documents, please select individual articles from the following table.

Register now and access more than 125,000 products

Variants

Register now and access more than 125,000 products

Customer Service: 0471 828 000 or text us on Whatsapp

Prices for customers after login

Chemical mortar consisting of 2 components, packaged and coded separately

Resistance to temperatures: up to +60°C, temporary maximum +100°C

Benefits:

- universal use: concrete, natural hard stone, solid masonry, steel, asphalt and wood

- for static and dynamic stresses

- free of solvents, diluents and plasticisers

- minimum shrinkage

- easy and quick to use

- very good mechanical properties

- resistance to atmospheric and chemical agents

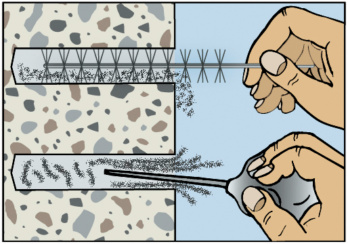

Holes should be thoroughly cleaned, possibly with blowing pump and machine brushes; for example: 4 pump strokes, 4 brushes and 4 pump strokes

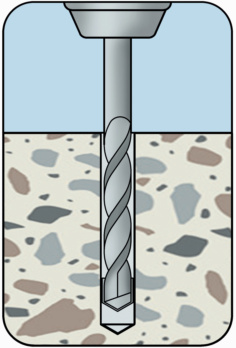

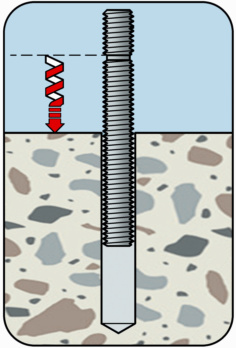

Drill hole.

Drill hole.

Clean drill hole. 4 x blow out/ 4 x brush out/ 4 x blow out) M20 and larger, blow out with compressor.

Clean drill hole. 4 x blow out/ 4 x brush out/ 4 x blow out) M20 and larger, blow out with compressor.

Insert reinforcing bar or threaded rod while turning.

Insert reinforcing bar or threaded rod while turning.

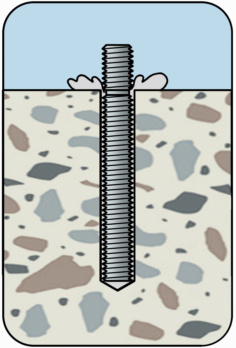

Check mortar filling quantity visually.

Check mortar filling quantity visually.

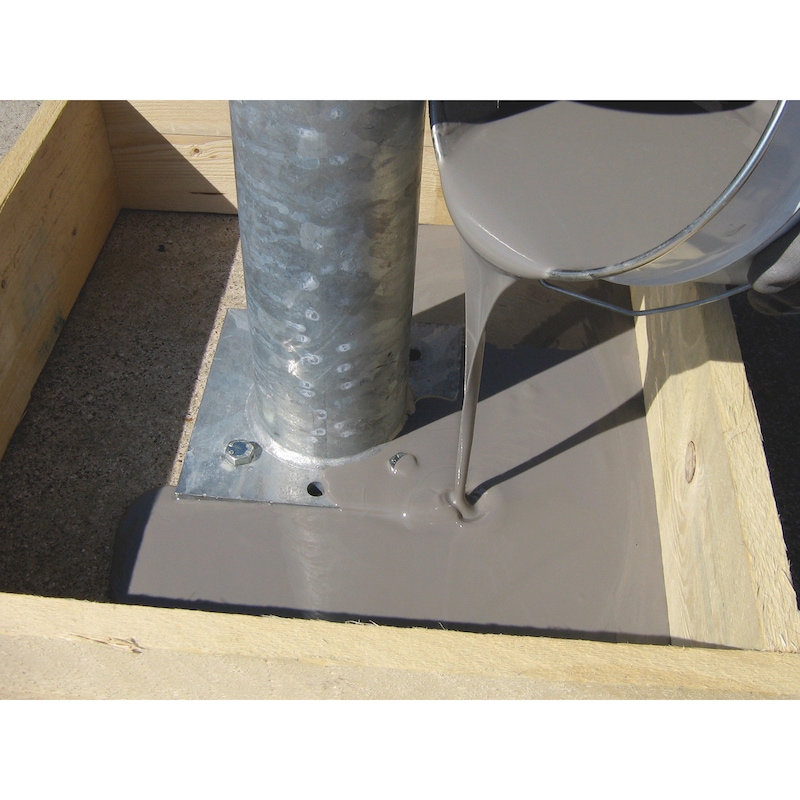

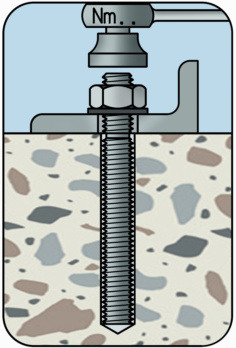

Install component, apply torque.

Install component, apply torque.

| Maximum recommended loads with threaded rods 5.8 and setting conditions: | Dimensions | M12 | M16 | M16 | M24 | M30 |

| Concrete C20/25 (compressed area) | Tensile/kN | 8 | 12 | 21 | 28 | 52 |

| Concrete C20/25 (compressed area) | Cut/kN | 6 | 11 | 17 | 24 | 39 |

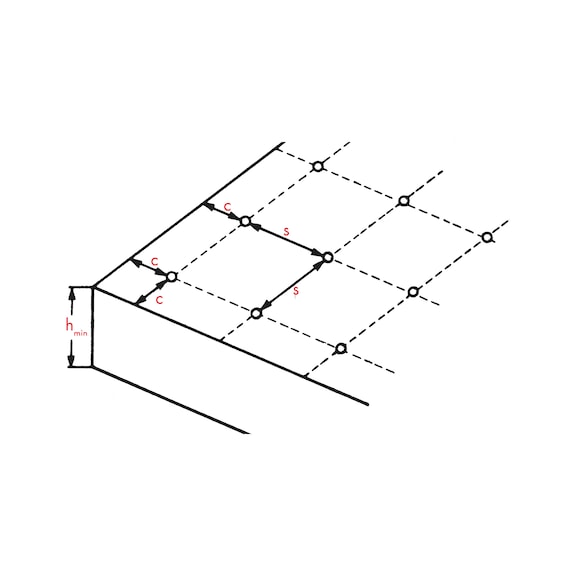

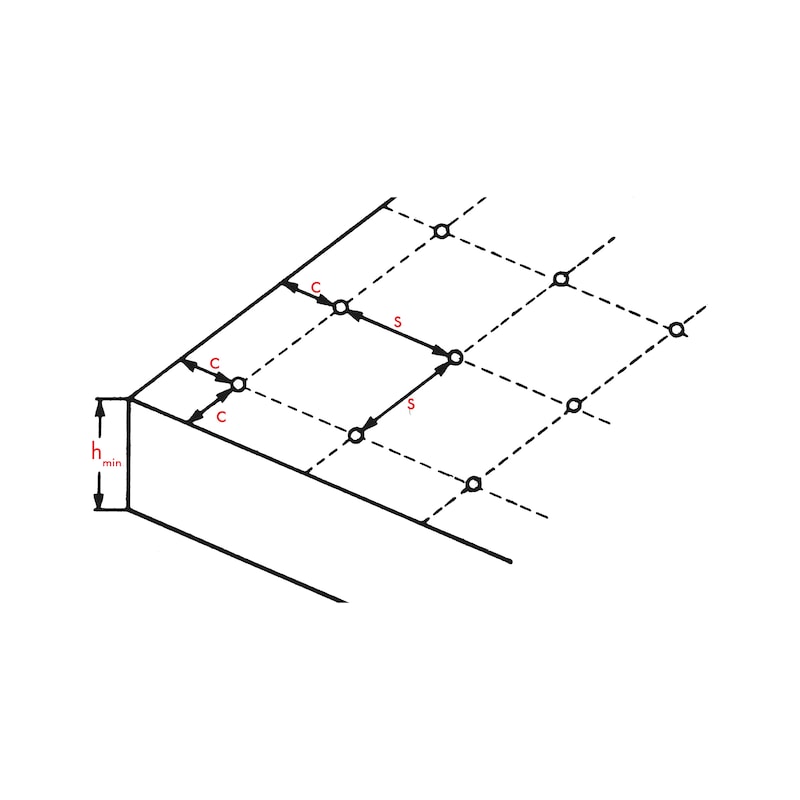

| Characteristic distance between anchors | scr,N/mm | 220 | 250 | 340 | 420 | 560 |

| Minimum distance between anchors | smin/mm | 55 | 65 | 85 | 105 | 140 |

| Characteristic distance from edges | ccr,N/mm | 110 | 125 | 170 | 210 | 280 |

| Minimum distance to edges | cmin/mm | 55 | 65 | 65 | 105 | 140 |

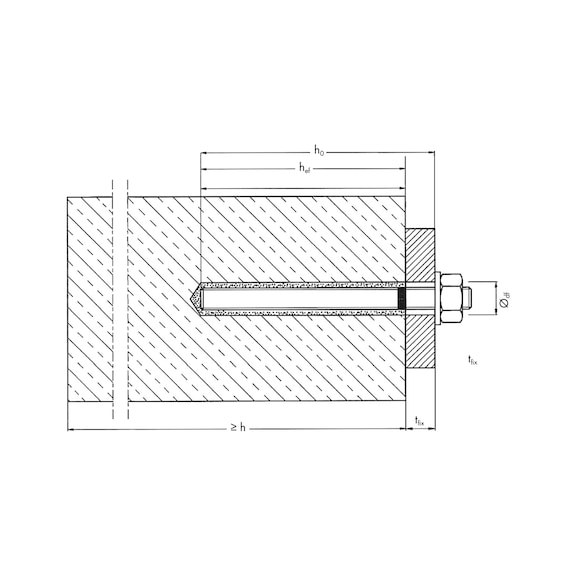

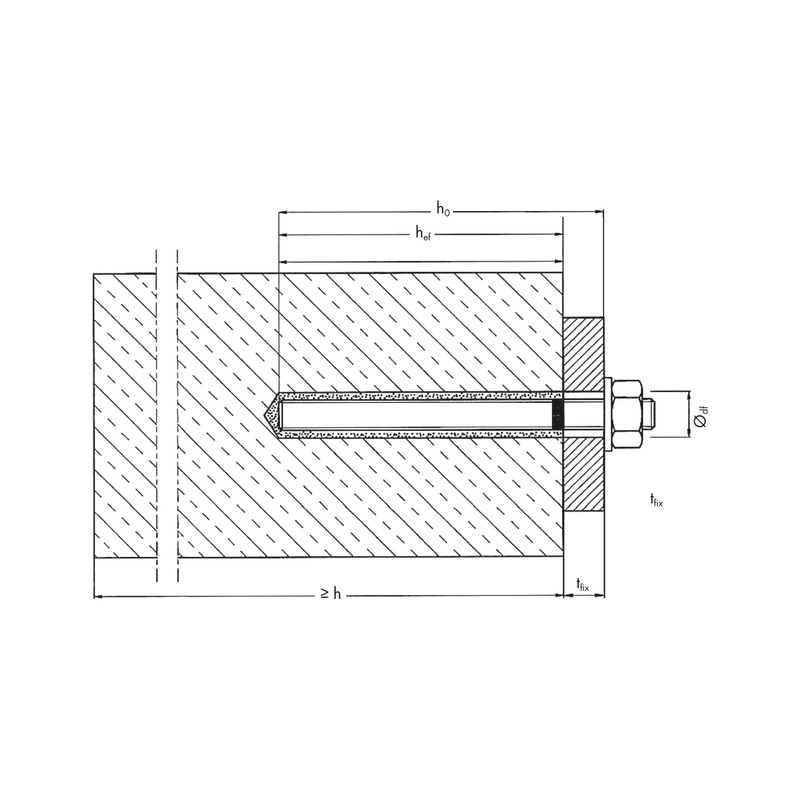

| Hole diameter | d0/mm | 14 | 18 | 24 | 28 | 35 |

| Hole depth | h0/mm | 110 | 125 | 170 | 210 | 280 |

| Anchoring depth | hef/mm | 110 | 125 | 170 | 210 | 280 |

| Min. surface thickness | hmin/mm | 150 | 165 | 210 | 250 | 320 |

| Tightening torque | Nm | 40 | 60 | 120 | 150 | 300 |

| (1kN = ~ 100kg) Notes: The loads described above refer to anchors mounted without influence from edges or other anchors. To achieve fastening with distances between anchors or from edges lower than the typical values, reduce the loads. The loads described above include a safety coefficient = 3 | ||||||

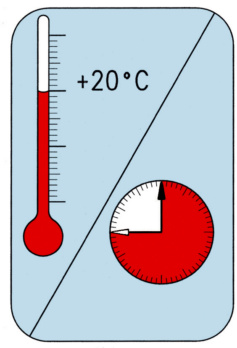

| Processing and hardening times: | |||

| Temperatures at the bottom of the hole (tip: use an infrared thermometer) | Max. times of processing minutes | Minimum hardening times/hours | |

| Dry surface | Wet surface | ||

| +5°C | 90 | 18 | 25 |

| +10°C | 70 | 15 | 24 |

| +20°C | 30 | 8 | 12 |

| +30°C | 25 | 3.5 | 5 |

| +35°C | 20 | 3 | 3.5 |

| Mortar temperature: minimum +5°C (tip: use an infrared thermometer) Storage temperature: between +5°C and +25°C, in a dry place and away from the sun | |||

For anchoring of:

- threaded irons bars and reinforcement bars

- road barriers, guard rails

- rails, cranes and trucks

- support girders

- road signs and poles

For filling of:

- joints and neighbouring cracks

- holes or corners in damaged structures

- filling of cavities in structural restoration

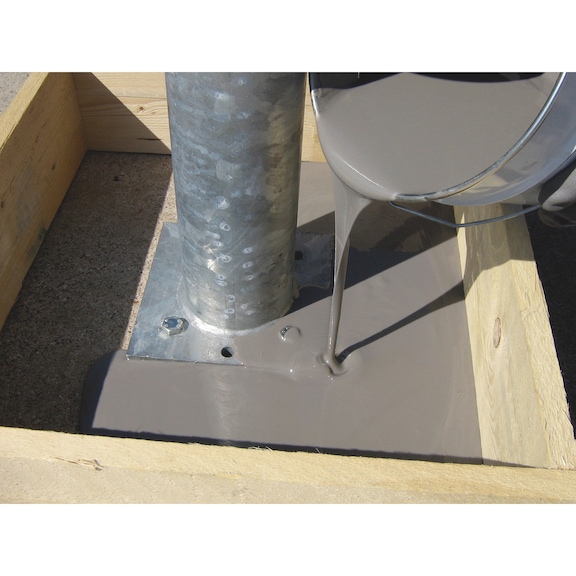

As grout:

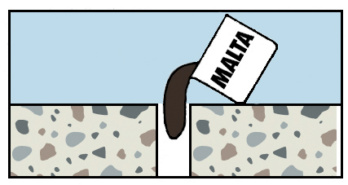

The product should be applied into holes in quantities such as to avoid overflowing immersion of the metal element to anchor

Narrow holes:

When pouring into narrow holes, it is necessary to ensure there are no air bubbles in the hole

As a structural adhesive:

Suitable for adhesion of metal, stone material, wood or other building materials with each other or with concrete; for joints or repair of concrete products. Apply by spatula, roller or brush in thicknesses of less than 3 mm

Cavity:

For filling joints or cracks, is it necessary to pour slowly and start from one side

Filling mortar:

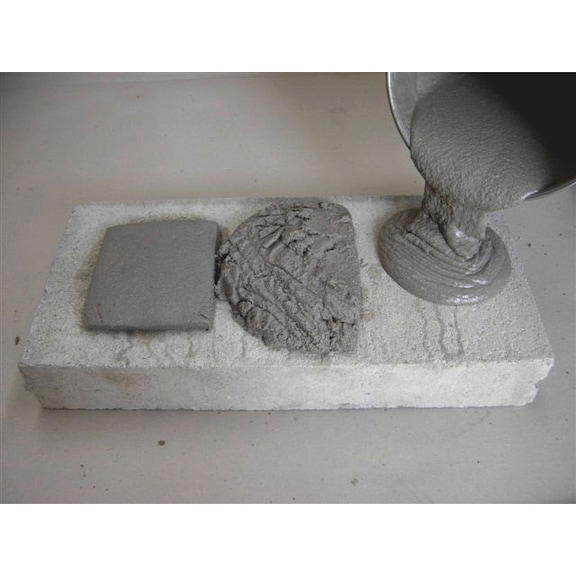

To fill cavities or perform structural restoration of large sizes, add while mixing in an appropriate container to each package of MC 100 from 15 to 25 kg of quartz sand with a particle size of 1.5 – 2 mm depending on the fluidity desired

Primer in construction joints:

Spread the product on the surface of old concrete with a brush or roller; proceed immediately, wet on wet, with the new layer

The underlying surface:

Must be clean, dry and free of oils, grease, dust or friable and loose parts. Metal surfaces should be sandblasted or restored by other means to remove traces of rust, calamine, etc. Temperature of surface min. +5°C, max. moisture of the surface 5%

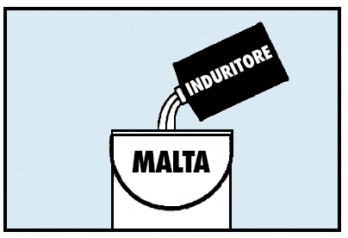

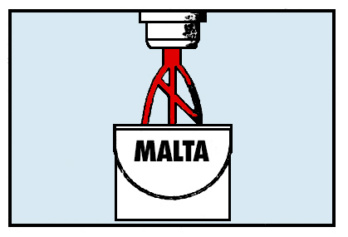

MC100 pourable chemical mortar:

Pour the hardener in the mortar bucket and slowly mix the two components with a mechanical mixer for 3 minutes making sure to also remove material along the sides of the package. The mixer paddle should be washed immediately after the job using a solvent

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!