For detailed information, other images and documents, please select individual articles from the following table.

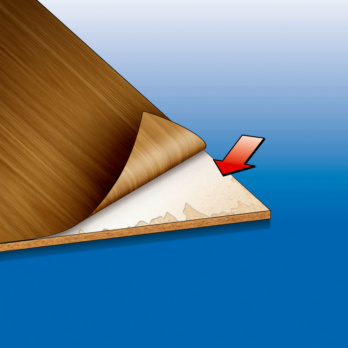

Cold wood glue for veneering D3

Glue for cold bonding of veneers and plastic laminates (melamine, phenolic resin) on wood panels (particle board, MDF, plywood)

Register now and access more than 125,000 products

Variants

Register now and access more than 125,000 products

- Suitable as an alternative to urea glues in the finishing of wood panels and derivatives

- The product is a thermoplastic, so if it remains in the press at over 70°C for extended periods, it may soften, cracks may form or veneers may lift. Never mix with products from other manufacturers. Mixture with lower-quality filled glues may cause reactions in the product

- On tannin-containing woods, the glue line may be coloured (chestnut, oak), a problem which is exacerbated by the presence of iron

- As this is a product designed for bonding of veneers, it has good resistance to solvents and is always thermoplastic. Therefore, in case of veneers with reduced thickness or that are very grainy, there may be problems during the painting stage

- Good resistance to water and solvents, which limits problems with bubbles during the painting stage

- Low outflow on the veneer surface

- Good filling strength, allows panel differences to be levelled (do not exceed slopes greater than 0.2 mm)

- Once hardened, the glue becomes semi-transparent, without changing colour

Class D3 under EN 204/205

Caution with woods containing tannin! With particular woods containing tannin (oak, chestnut) or wood with easy oxidation (cherry) changes in colouring or spots may occur. Protect from frost! Do not apply below 6/10°. Gluing at temperatures below 15°C may be ineffective; storage at temperatures below +5°C and above 35°C may damage the product

In the summer, with increased temperatures, the open time is significantly reduced

While the technical advice given is based on our experience and should be followed, it is purely indicative and must be confirmed through extensive practical tests. This does not relieve the purchaser of their responsibility to personally test our products to see whether they are suitable for the intended use

Class D3 under EN 204/205

For gluing in indoor and outdoor environments subject to short and frequent exposure to water and condensation. Does not exude

Suitable for furniture panels

Table tops

Kitchen tops

Doors

Production of hollow-core and finishing with veneers: fir, pine, poplar, beech, oak, cherry, walnut, chestnut

Mix well before each application. Apply glue evenly with a glue roller, brush, dispenser, stainless-steel or plastic serrated trowel or a pneumatic spreading tool. Avoid contact with ferrous materials, which may cause bluish discolorations when in contact with the tannin of the wood. The curing time and bonding speed are influenced by temperature, humidity, porosity of the material and the amount of product used. The best results are obtained in the following conditions: temperature of the product, surface and environment 18-20°C; humidity of wood: 8–12%. Residues of fresh product can be removed with water, hardened adhesive with paint thinner, acetone or paint cleaner.

Open time:

10 – 20 minutes. This is the maximum time that can elapse between spreading and pressing at a temperature of 20°C both for the environment and for the wood, coating of 150 g/m2, air humidity 50% and moisture content of the wood 10%

This time is reduced if:

- spread less than 150 gr/m2

- the temperature is above 20°C

- air humidity is below 50%

- the moisture content of the wood is below 10%

It increases if:

- if spreading more than 150 gr/m2

- the temperature is below 20°C

- air humidity is above 50%

- the moisture content of the wood is above 10

Setting time:

- Medium-fast 20 to 30 minutes. This is the time that the item should be allowed to set, at a temperature of 20°C, both for the environment and for the wood, application of 150 g/m2, air humidity of 50%, moisture content of the wood 10%

- for further processing it is preferable to wait at least 24 hours

This time is reduced if:

- spread less than 150 gr/m2

- the temperature is above 20°C

- air humidity is below 50%

- the moisture content of the wood is below 10%

It increases if:

- if spreading more than 150 gr/m2

- the temperature is below 20°C

- air humidity is above 50%

- the moisture content of the wood is above 10%

Viscosity:

- not to be confused with density; this is the difficulty of the product to flow

- 12500 ± 2500 mPas, medium – high

- Do not dilute the product

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!