For detailed information, other images and documents, please select individual articles from the following table.

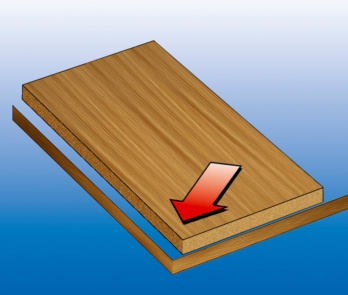

Hot melt glue for automatic edge banding

Solid hot-melt ethylene-vinyl acetate-based glue for bonding edges

Register now and access more than 125,000 products

Variants

Register now and access more than 125,000 products

- Excellent adhesion and heat resistance properties

- Glue line barely visible thanks to product transparency

- The excellent balance between melting speed, open time and viscosity makes it a highly versatile product

- Suitable for application of edges of each type. On laminate and solid wood edges it is preferable to use suitable primer. Do not exceed thicknesses greater than 6 mm when applying to solid wood edges

- The product is a thermoplastic, therefore, if it remains in the press at over 80°C for a long time, it may soften and cracks may form

- On edges already treated with primer during production, pay attention to the age (usually expires after 6 months)

- If the rolls of the edges are stored in a dusty environment, ventilate the coils with plenty of air before use

- If the product flows out too much during application, try the following solutions in order:

1) Reduce the amount of adhesive

2) Increase the temperature by 10–15°C

3) Decrease the initial temperature by 10–15°C

Check the temperature of the glue on the rollers frequently. At temperatures that are lower than those recommended for application, there is a decrease in open time with consequent defective bondings. At higher temperatures, the adhesive may decompose and lose colour, viscosity and adhesiveness. Gluing cold or damp surfaces may cause bonding defects due to the decrease in open time. Bad quality bonding may result from the type of edge or the presence of release agents on the surface being treated. Therefore a preliminary test is recommended

We recommend always using melamine and plastic laminate edges, particularly in winter

The edges must be free of dust; blow compressed air to remove any dust before use

Protect the product from moisture, store in a tightly closed cool and dry place

In winter, with decreasing temperatures, the open time is greatly reduced. It is therefore necessary to increase the temperature on the roller

While based on our best experience, the technical advice given should be considered purely as guidance, and must be confirmed through comprehensive practical tests. It does not relieve the purchaser of their responsibility to personally test our products to see whether they are suitable for the intended use

For interior use only. For bonding sliced edges, polyesters, melamine, plastic laminates, PVC and ABS treated

Open time:

Underlying material. This is the maximum time that can elapse between the coating and pressing. Hot-melt adhesives are highly affected by the application temperature, the environment and the materials used. If it is too short, the glue line may show roller marks (normally round dots)

Setting time:

Medium-fast. Hot melt adhesives are highly affected by the application temperature, the environment, the materials used and feed rates

Viscosity:

- not to be confused with the density; it is the product's resistance to flow

- medium - high

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!