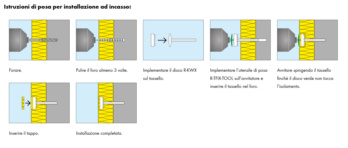

For detailed information, other images and documents, please select individual articles from the following table.

Screw-in anchor for insulation panels R-TFIX-8S

With galvanised steel screw

Register now and access more than 125,000 products

Variants

Register now and access more than 125,000 products

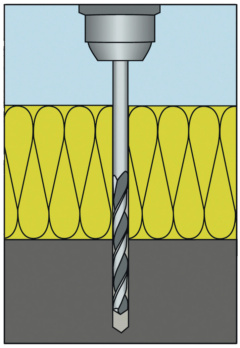

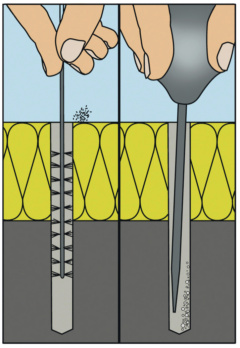

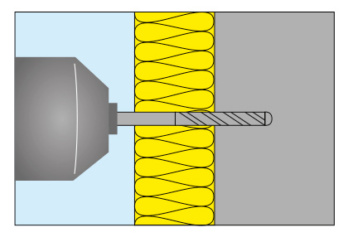

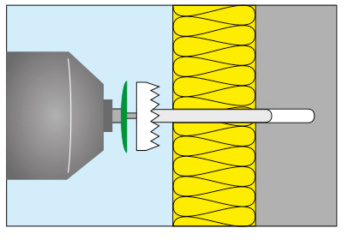

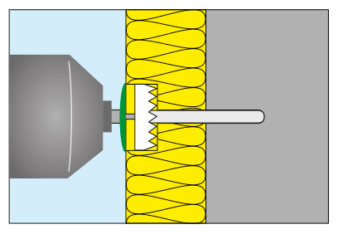

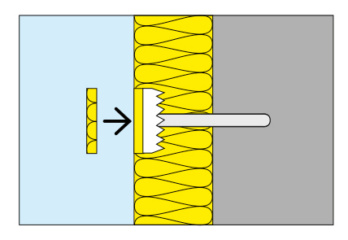

- Screw-in (TX40 drive): installation is gradual, thereby minimising disturbance in the finishing layer and the reinforcement material

- Can withstand higher loads than traditional hammer-in insulation panel anchors: fewer anchors are required per square metre of insulation, which saves considerable time and money

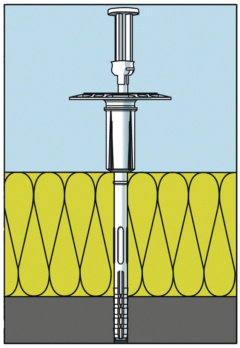

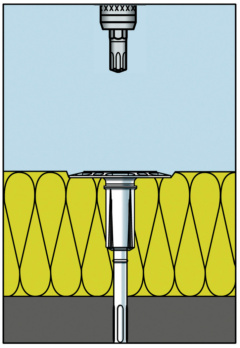

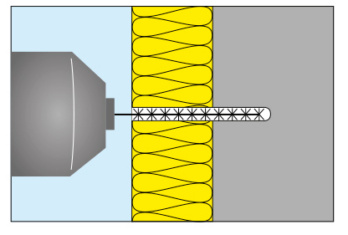

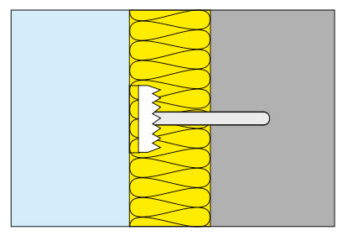

- Option of flush mounting to further minimise the thermal bridge and prevent stains appearing on the finishing layer

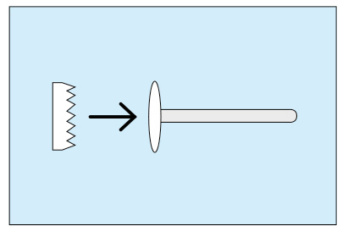

- Polypropylene anchor preassembled with galvanised steel screw with fibreglass-reinforced polyamide head

- Thanks to its particular geometry, the anchor can transfer high loads to the support with a shallower anchoring depth

- Heat transfer χ = 0.002 W/K

For soft insulation panels (e.g. made of rock wool), the KWL retaining plate (dia. 90 mm) can be used

* + 10 mm for flush mounting

1) A tolerance of 10 mm is already taken into account (for example, to allow for an adhesive). The presence of layers of plaster on older buildings, for example, reduces the maximum thickness of the insulation panel. For this reason, the specific installation situation should always be considered when calculating the length of the anchor

The insulation panel must have a minimum thickness of 60 mm in the event of flush mounting

Rk, Rd, Ramm are respectively characteristic, design and permissible resistance values. The characteristic and design values are obtained using statistical methods and safety factors. The permissible value is obtained from the design value by applying an additional conventional safety factor of 1.4. For those unfamiliar with the characteristic and design values, we recommend using the permissible strength value by checking that it is greater than the maximum load acting on the anchor

| Supports A + B + C + D | Support E | ||||||

| Min. depth of hole [mm] | Min. depth of anchor [mm] | Max. thickness of insulation panel1) [mm] | Min. depth of hole [mm] | Min. depth of hole mm | Max. thickness of insulation panel1) mm | Length of anchor [mm] | Art. |

| 35* | 25* | 80 | 55* | 45* | 60 | 115 | 5921 399 115 |

| 100 | 80 | 135 | 5921 399 135 | ||||

| 120 | 100 | 155 | 5921 399 155 | ||||

| 140 | 120 | 175 | 5921 399 175 | ||||

| 160 | 140 | 195 | 5921 399 195 | ||||

| 180 | 160 | 215 | 5921 399 215 | ||||

| 200 | 180 | 235 | 5921 399 235 | ||||

| 220 | 200 | 255 | 5921 399 255 | ||||

| 240 | 220 | 275 | 5921 399 275 | ||||

| 260 | 240 | 295 | 5921 399 295 | ||||

| * + 10 mm for flush mounting 1) A tolerance of 10 mm is already taken into account (for example, to allow for an adhesive). The presence of layers of plaster on older buildings, for example, reduces the maximum thickness of the insulation panel. For this reason, the specific installation situation should always be considered when calculating the length of the anchor. The insulation panel must have a minimum thickness of 60 mm in the event of flush mounting | |||||||

| Base material | Category | Rk characteristic resistance to extraction | Ramm permissible (or recommended) load |

| Permissible maximum loads and installation conditions: | |||

| Concrete C12/15 | A | 1.20 kN | 0.60 kN |

| Concrete C16/20 - C50/60 | A | 1.50 kN | 0.75 kN |

| Solid bricks | B | 1.50 kN | 0.75 kN |

| Perforated bricks | C | 0.90 kN | 0.45 kN |

| Lightweight concrete | D | 0.90 kN | 0.45 kN |

| Autoclaved aerated (cellular) concrete | E | 1.20 kN | 0.60 kN |

| Min. spacing between anchors | A, B, C, D, E | 100 mm | |

| Min. distance from edge | A, B, C, D, E | 100 mm | |

| Min. thickness of support | A, B, C, D, E | 100 mm | |

| (1 kN ~ 100 kg) | |||

For fastening insulation panels in external thermal insulation composite systems (ETICS), e.g. expanded polystyrene (EPS), rock wool, cork and polyurethane, or lightweight panels made of wood wool

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!