For detailed information, other images and documents, please select individual articles from the following table.

Rope splicing set WLAKITLM

Robust lifeline — fall arrest systems

Register now and access more than 125,000 products

Variants

Register now and access more than 125,000 products

Rope splicing and tensioning set for corrugated sheet metal anchor points WCLM25 and WCLM25R

Set contains:

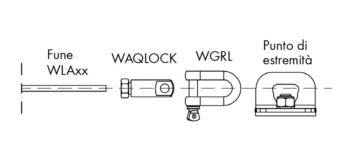

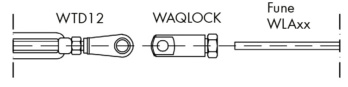

- 2 dual-cone attachments WAQLOCK

- 1 shackle WGRL1 1 turnbuckle WTD12

- 1 turnbuckle WTD12

Tension reducer and dual-cone attachments in A2 (AISI 304) stainless steel, shackles and turnbuckle in A4 (AISI 316) stainless steel

Direct splicing of the rope using the special dual-cone attachments means a reduction factor for the nominal rope load of just 0.9 can be used

Advantages of A2 (AISI 304) and A4 (AISI 316) stainless steel:

Remains unchanged over time, being resistant to weather induced corrosion

Because of its intrinsic characteristics, the material can dissipate more energy, in the event of a fall, compared to zinc-plated steel, thereby reducing the need for maintenance operations on the attachments and on the connection structure

Tension reducer - requirements and intervention:

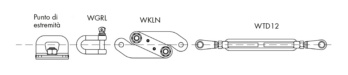

- the tension reducer (patented) considerably reduces the tension on the end points in the fall arrest phase

- a tension reducer must be present for each section of rope

- at the WCLMxx and WCLMxxR corrugated sheet metal anchor points, the tension reducers are already integrated on the anchor points themselves

- in the event of a fall, the tension reducer extends (see fig. A and fig. B), breaking the safety rivets. It is therefore essential to carry out a non-routine inspection before using the system again

Cable splicing:

Please see below for the assembly sequences for the WAQLOCK dual-cone attachment, to be spliced on both ends of the cable

Mounting of the anchoring line:

Each section of cable requires the use of a WLAKIT wall set or, with corrugated sheet metal anchor points WCLMxx and WCLMxxR, a WLAKITLM wall set

Warranty:

10 years for materials (from the date of purchase)

Anchorage to the load-bearing structure:

The surface must be assessed and the anchor must be sized by a qualified technician. The suitability of the surface for absorbing the stress exerted by the falling operator must always be tested (see standard UNI 11560:2022)

Certifications:

The anchoring line has undergone the tests required by standard UNI 11578:2015 and is compliant with type C. The ideal number of operators for using this device is stated in the catalogue. The certification will no longer be valid if the product is disassembled, altered, modified or improperly installed. Certifications can be downloaded from the website: www.wuerth.it/progettisti/prodotti/linea-vita/

Regular inspection:

The anchoring system is subject to regular mandatory inspection at intervals of no more than 2 years, as required by Point 9.2.3. of standard UNI 11560:2022. The regular inspections must be performed by the intermediate installer and/or qualified technician, always assuming liability for the activity undertaken. The checks to be performed refer to the table 1, 2 and 3 of UNI 11560:2022

Further information:

Please refer to the information pages, the installation and operation manual and the handbook for the system supplied with the products. These documents can be downloaded from the website: www.wuerth.it/progettisti/prodotti/linea-vita/

For creating anchor lines to protect against falls from height

Only for splicing and tensioning WLA A4 (AISI 316) stainless steel ropes Ø 8 mm made up of 19 strands

Suitable for use by a maximum of three operators simultaneously, connected to the rope using appropriate personal protective equipment (PPE); the PPE of each operator must not, in case of a fall, generate a load greater than 6 kN

Suitable for anchor lines that deviate from the horizontal position by no more than 15°

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!